You are here

Workflow Optimization

Workflow optimization is an important way to reduce costs and provide better services for patrons. With inefficient workflows, things take longer and cost more to get done. In addition, rethinking workflows is a critical part of the process of incorporating new technologies.

There are many methodologies for optimizing workflows such as Lean based on the Toyota Production System, and Six Sigma. Lean methodologies focus on eliminating waste and improving quality. Six Sigma focuses on the "quality of process outputs" and removing defects. And some practicitioners have been trained in a combination of both methodologies called Lean Six Sigma. Lori Ayre of The Galecia Group is a Green Belt in Lean Six Sigma and DFSS (Design for Six Sigma). All of these methodologies can be applied to the library environment with excellent results.

Areas that often yield the most dramatic benefits from workflow optimization are delivery systems, back office operations (technical services, processing, cataloging, and ILL) as well as materials handling functions (bookdrop check-in, holds pulling, sorting, etc.)

Learn more about Workflow Optimization and Lean>>

When introducing new technology, especially technology that reduces the staff workload and focuses more on self-service, it is important for libraries to change their service model while embracing the values that drive the organization. The Galecia Group, in partnership with Cheryl Gould of Fully Engaged Libraries, offers workshops and consultations that get at these issues.

Here's a description of some of the packages we can offer:

RFID Technology Consult, half day

Get answers to commonly asked questions about RFID (as well as questions that SHOULD be asked but often are not). How exactly does RFID work and does it really matter what tag I use or even what vendor I use? Does my ILS make a difference? What standards am I supposed to include in my RFP and what do they mean? What's a data model and should I care about that? Isn't RFID just a barcode that works over the air instead of optically? What kinds of things are being developed by RFID vendors and how does that come into play with other technology decisions I make? What are the range of costs for tags, equipment, services? How do people do the tagging part? Consultant: Lori Ayre

Project Definition Workshop, 1 day

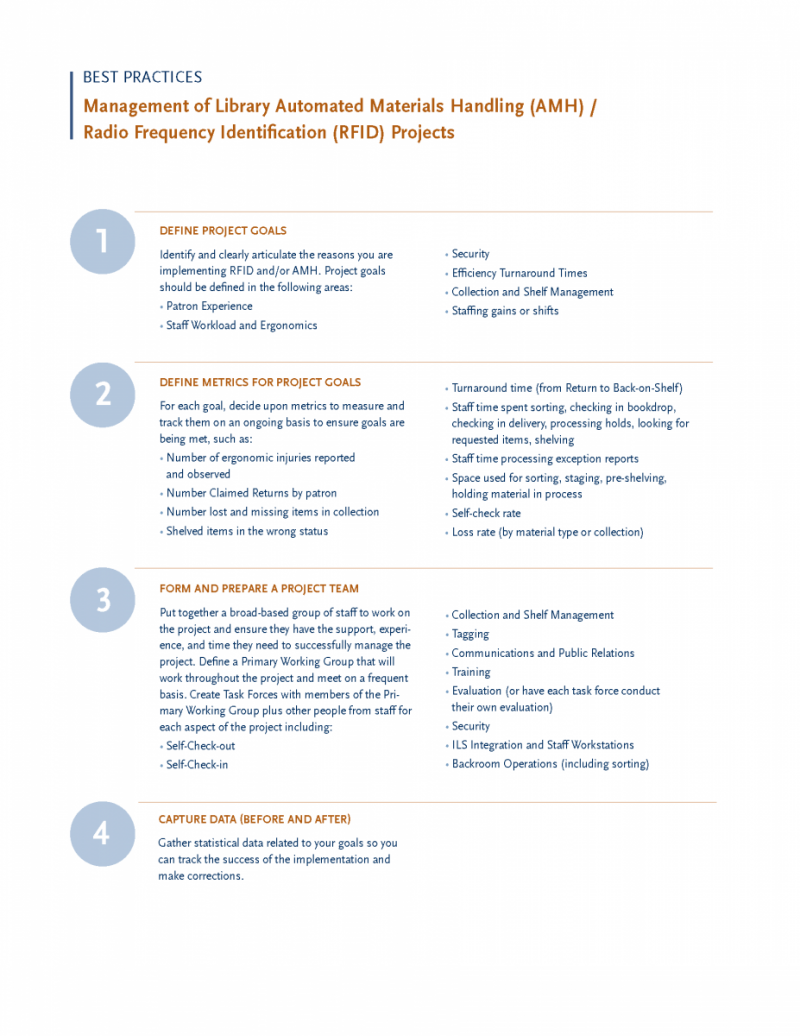

Work with management to clarify objectives for implementing RFID/AMH and to define priorities because different objectives tend to conflict so the library needs to be clear what their topmost objectives are. Often, there is a mismatch between what the library thinks will happen simply by implementing RFID or throwing a sorter into the mix. This will help everyone understand more clearly what subsequent steps need to be taken based on their stated priorities. The workshop works with the library to tease out those priorities, do some reality-checking and education about the technology, and address some of the choices their priorities dictate. By the end of the day the library will have clarity about what they are working to accomplish and what needs to happen to achieve those objectives including the importance of staff buy-in (which will be the subject of the Project Engagement Workshop). Workshop Leaders: Lori Ayre, Cheryl Gould

Project Engagement Workshop, 1 Day

Staff engagement is one key to a success of every technology implementation. In this workshop, we work with line staff to clarify the objectives for introducing the technology. We'll spend time explaining how any new technology being proposed that could, or would, change their current workflows and begin to engage the staff in a productive exploration of what they'll be able to do that they cannot now do. The objective of the workshop is to help staff work through their anxieties about the changes while getting them in touch with the key services patrons need from them so they can see the technology as a way to improve the ways the library is serving the community. By the end of the day, most (never all) will be excited about the project. Workshop Leaders: Lori Ayre, Cheryl Gould

Technology Integration and Workflow Consultation, five on-site days over 3 months

Examine and document key materials handling workflows and work the library to optimize their use of existing resources. This is done by identifying opportunities for reducing overall handling and number of touches, eliminating wait times, reducing transport of material, optimizing the space for the work, and eliminating nonproductive steps. Throughout the project, Lean principles are introduced and applied to the environment. Introducing concepts such as visual management and continuous improvement will empower the library to continually optimize their workflows even after the consultation ends. Consultant: Lori Ayre

Projects and Presentations

| Date | |

|---|---|

|

Client: |

2021 - 2022 |

|

Client: |

20252022 - 2025 |

|

Client: |

20242022 - 2024 |

|

Client: |

20232021 - 2023 |

|

Publication-Presentation: |

2017 |

|

Publication-Presentation: Event/ Publication: Strategic Library Webinar, April 27, 2016 |

2016 |

|

Publication-Presentation: |

2015 |

|

Publication-Presentation: Event/ Publication: American Library Association Annual Conference, Las Vegas |

2014 |

|

Client: |

20142014 |

|

Client: |

20142013-2014 |